In the competitive field of industrial manufacturing, end quality is proportional to the precision of processing. When accurate temperature control isn’t a goal for facilities using industrial ovens such as processing plants involved in curing coatings, hardening metal or baking food products it is still essential. Even relatively small changes can have disastrous consequences with, for example, binned batches and energy wastage and compromised product quality. The supply voltage of the mains is unstable and very few people take it into account, though it’s a huge problem when we develop electronic devices. So here is where a good 220V power regulator becomes important to your operational readiness.

Voltage Stability is Critical for Proper Oven Operation

Industrial ovens, notably those equipped with electric heating elements, are designed to work at a given voltage and frequently 220 V. The consumption of power by the heating elements is proportional to the square of its line voltage. As a result, a relatively small difference in incoming voltage can lead to quite a different power output - with an obvious impact on the temperature of the oven cavity. For example, reducing the line voltage to 200V will result in less heat generated by the heating elements and makes it difficult for the oven to reach or maintain setpoint. Alternatively, a transient increase to 240V wilI cause overworking of the elements which may in turn cause them to overheat and become damaged, while compounding any burning on the product. When that is not protected from voltage fluctuations, the interior temperature controller of the oven struggles continuously with these outside voltage variations causing inconsistent heating, "hot and cold" areas in your oven, and it will be unable to maintain a stable temperature profile during curing or baking.

How a 220V Stabilizer Provides Accuracy and Protection

A regulator of voltage wants to keep an eye on your industrial oven. Based on a thorough monitoring of the line voltage it will automatically compensate any under or overvoltage conditions in the range of 165V to 275V and provide stable output power at 220V with no time shift. With a top of the range regulator from this reliable specialist manufacturer, Quzhou Sanyuan Huineng Electronic Co., Ltd, you are able to shield your delicate thermal processing machinery safely from the grid's inconsistencies. Such steady current supply enables the oven's own thermostat and control system to perform its operations properly. The result is unmatched temperature uniformity throughout our series chamber. Each product is subjected to the same, uniformed heat application, batch after batch; which results in a consistent color and proper curing as well as complete moisture evaporation, ultimately providing you with a reliable final desired product. In addition, because the regulator blocks voltage spikes and sags, it reduces stress on the oven's heating elements and electrical parts, resulting in a longer service life for all components of the device with fewer maintenance calls.

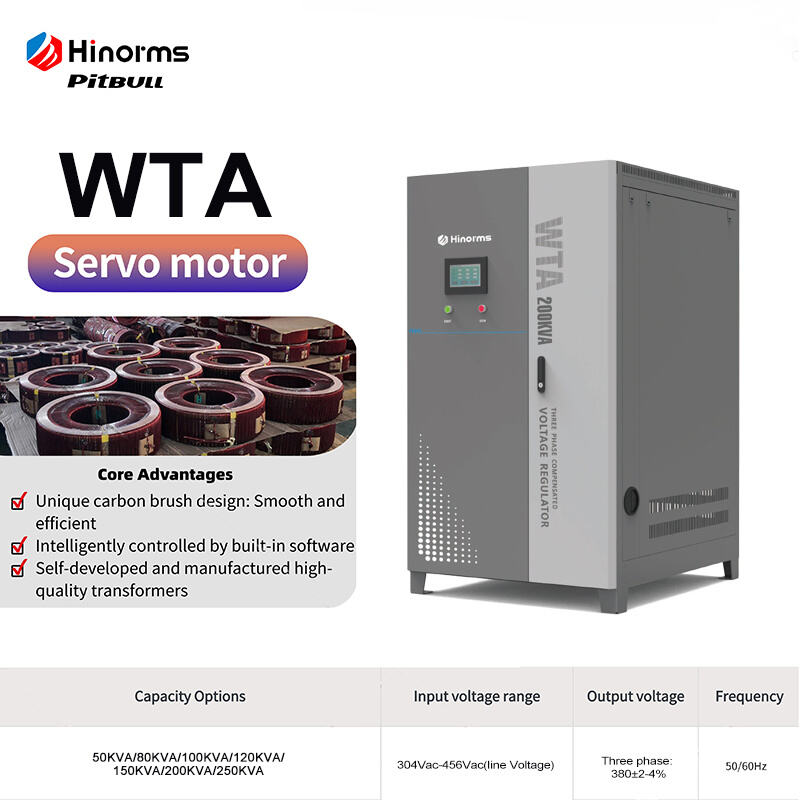

Key Features for Industrial Applications

Not every voltage-guard has what it takes to survive in a rugged environment like an industrial plant. When choosing a regulator for an industrial oven, there are several key features that you must make sure it has. The unit would need to be of a high-power capacity (kVA rating) in relation to the surge current draw and load of the heating elements. A very quick response is needed to correct voltage sags or swells as they occur and not allow them to affect the temperature of your oven. Construction must be strong enough to resist extremely high ambient temperatures near ovens. From Quzhou Sanyuan Huineng Electronic Co., Ltd. products are designed with these hard-operating requirements in mind to provide reliable performance under industrial use, cost-effective durability and control of temperature for critical applications hot process.

Conclusion: Quality and Efficiency as an Investment

Adding a dedicated 220V voltage regular is one of the few investments that can quickly pay for itself, making this addition cost-effective and a much-needed upgrade. It turns your industrial oven into a consistent and accurate heat processing machine. From the power supply down, you have a uniform temperature for your processing needs to ensure that you are getting the highest quality product and productivity. "Well-established companies who cannot risk any compromise, voltage regulation should not be just an accessory to their equipment but a significant part of a well-controlled operation.